Magwise

Focused on die casting, creating value for customers by providing top-notch products and solutions.

Focused on die casting, creating value for customers by providing top-notch products and solutions.

About Us

Guangdong Magwise Precision Technology Co., Ltd. was established in 2015, located in Dongguan, Guangdong, with a factory area of 11,000 square meters and more than 150 employees. Magwise boasts first-class production equipment and testing instruments, continuously optimized production processes, and a comprehensive quality control system. It has achieved IATF16949 certification and SONY's AQAS certification, making it a GP partner of SONY. Magwise Precision specializes in the production of magnesium and aluminum alloy die-casting and machined products, particularly excelling in products requiring high surface treatment, high precision dimensions, and high-quality stability.

Magwise Precision can provide customers with one-stop solutions including DFM (Design for Manufacturing) scheme design, prototype processing, mold design, die casting, machining, surface treatment, and APQP (Advanced Product Quality Planning) control. Our services cater to clients in the automotive, smart devices, medical, and aviation sectors. Magwise Precision's products are extensively used in products of world-class brands such as SONY, GM, NVIDIA, BOEING, CRESTRON, and VW, where the quality of Magwise Precision's products has been highly recognized by customers.

In the future, Magwise Precision will continue to adhere to the philosophy of 'respect and people-oriented', constantly improve its processing capabilities and management level, and provide top-tier products and services for first-class customers.

We focus on crafting every detail, meeting the needs of global customers with manufacturing capabilities that exceed expectations.

On our production line, every technological innovation and refinement of each process aim to improve manufacturing quality and efficiency. We pursue not only products of unparalleled precision but also strive to create leading die-casting solutions for global customers, setting new benchmarks in the industry.

With diverse materials and precision manufacturing, we offer a one-stop manufacturing solution.

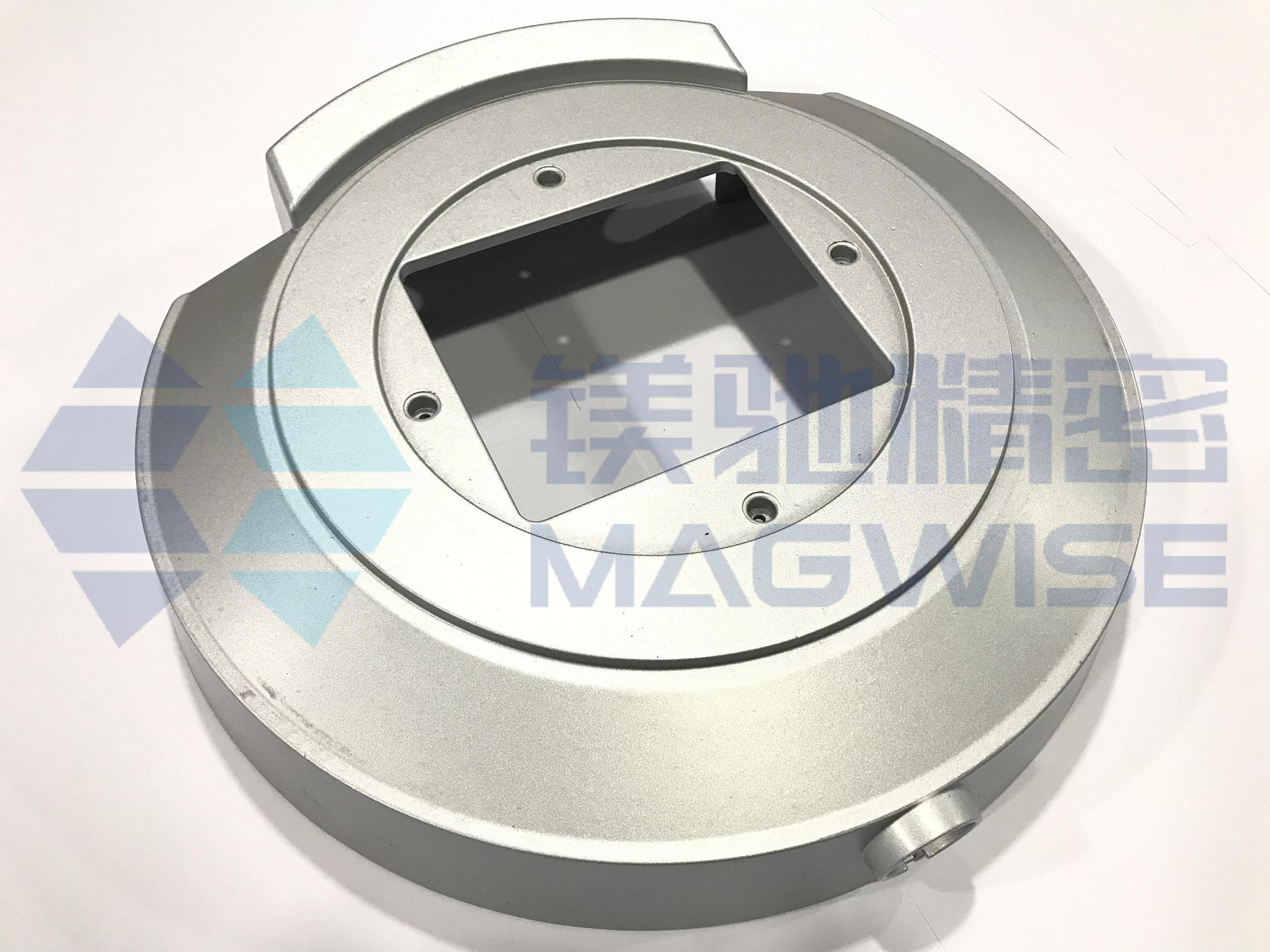

Smart parking lock case

Aluminum alloy

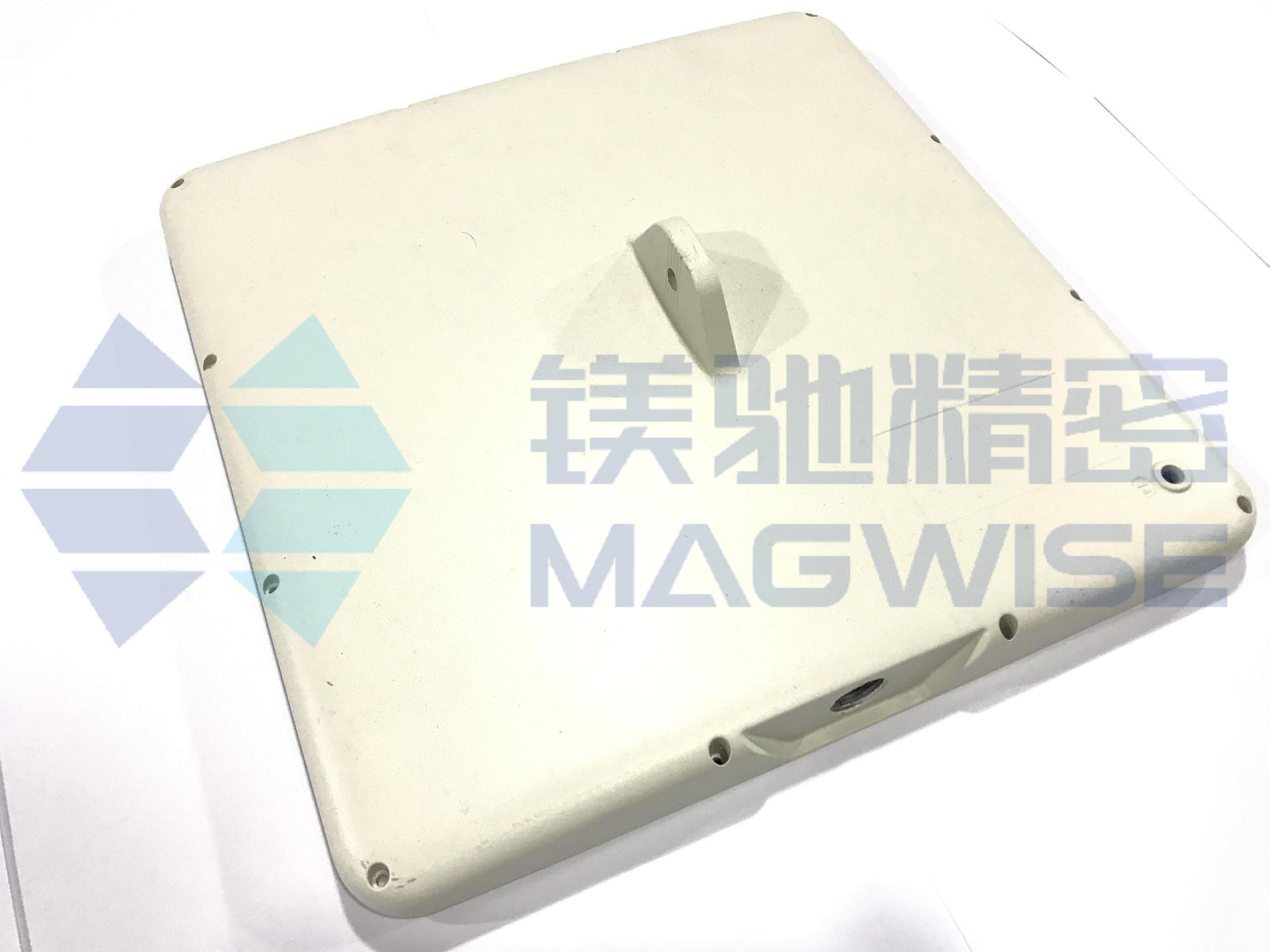

Medical device monitor case

Aluminum alloy

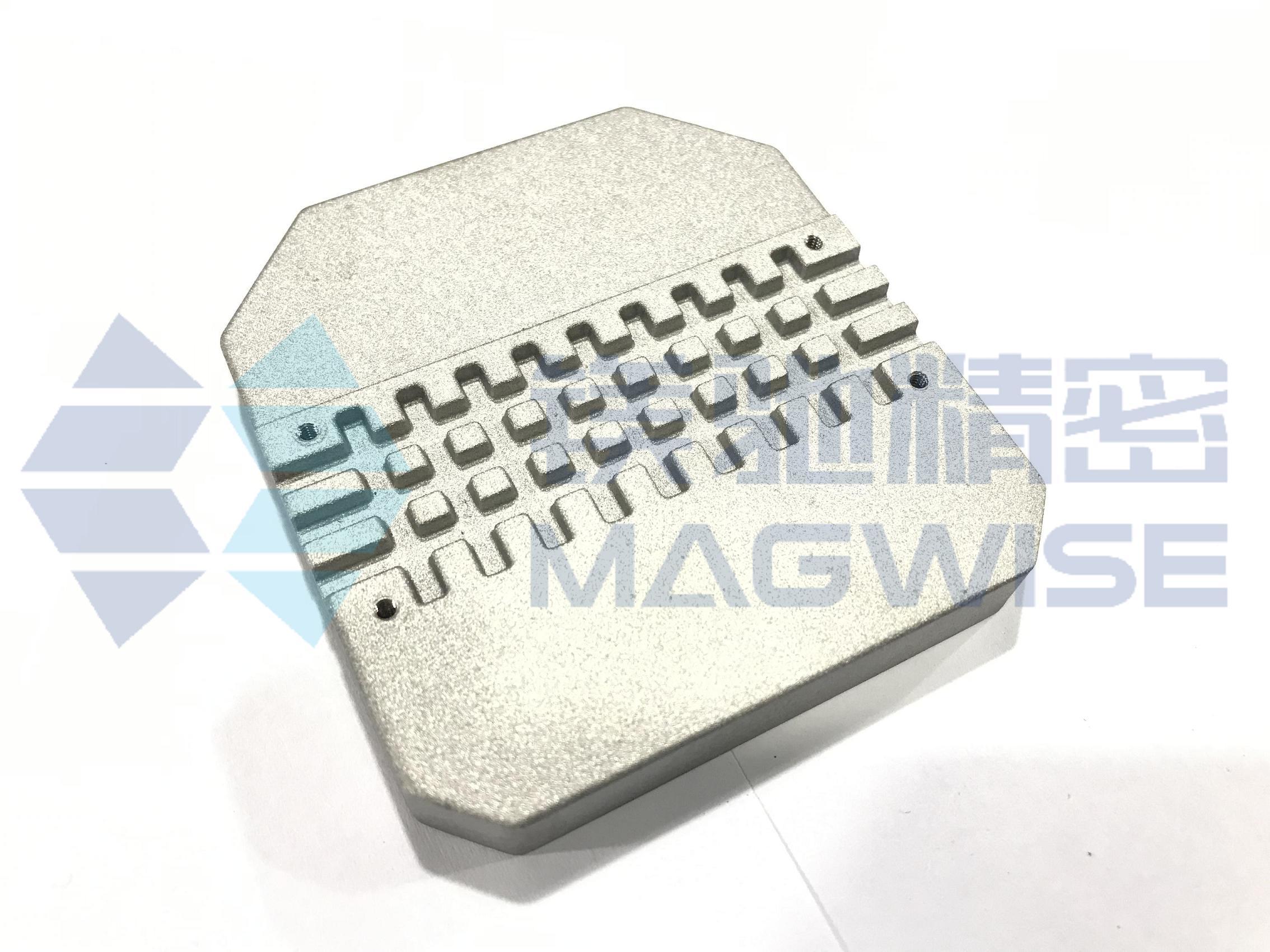

Camera bracket

Aluminum alloy

Power tool accessories

Makita Japan

Omron medical device arm

Omron

Omron navigation case

Omron

Aircraft equipment handle

Aluminum alloy

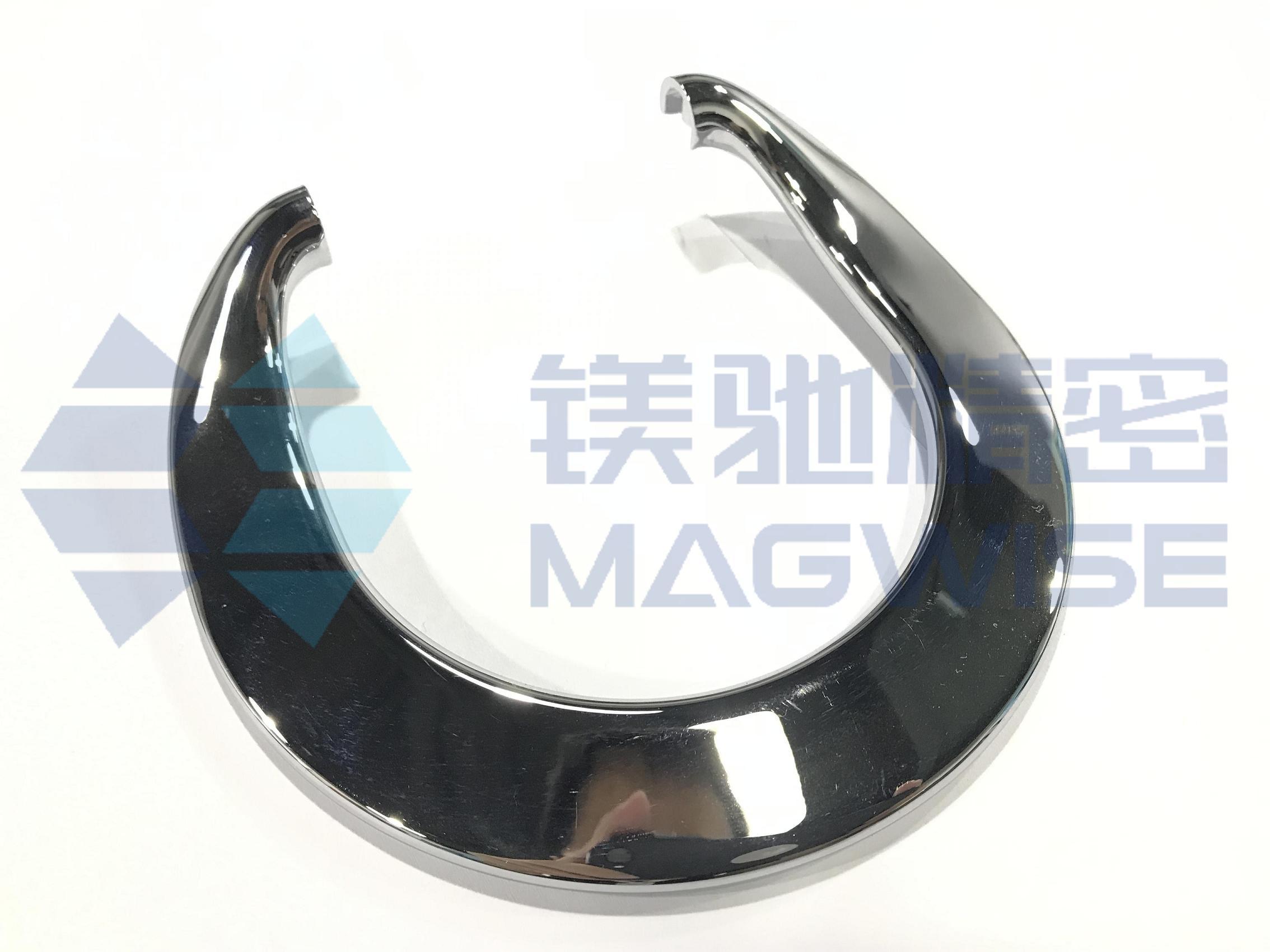

Juicer handle

Aluminum alloy

High-speed train hinge

Aluminum alloy

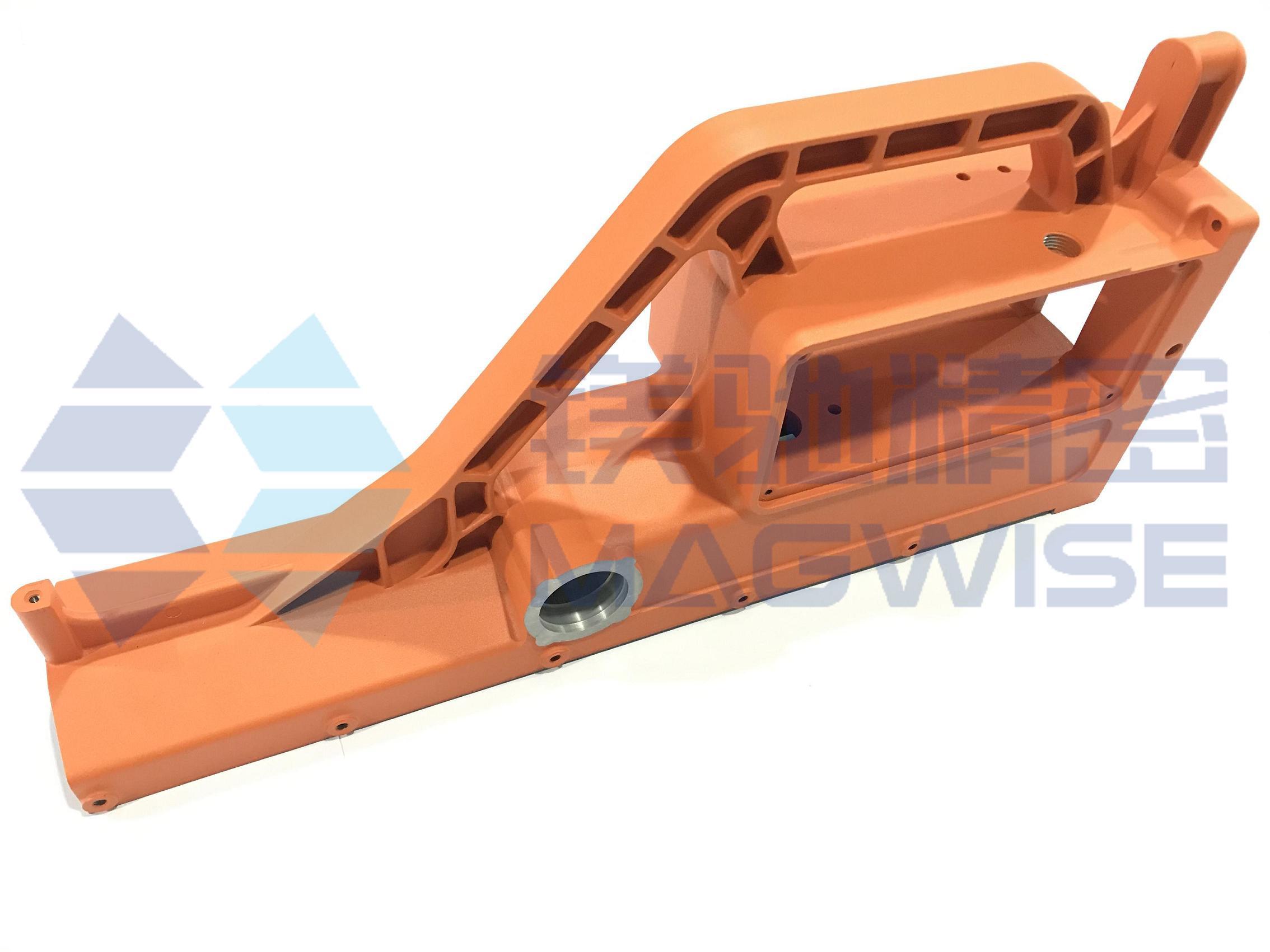

Electric saw handle body

Aluminum alloy

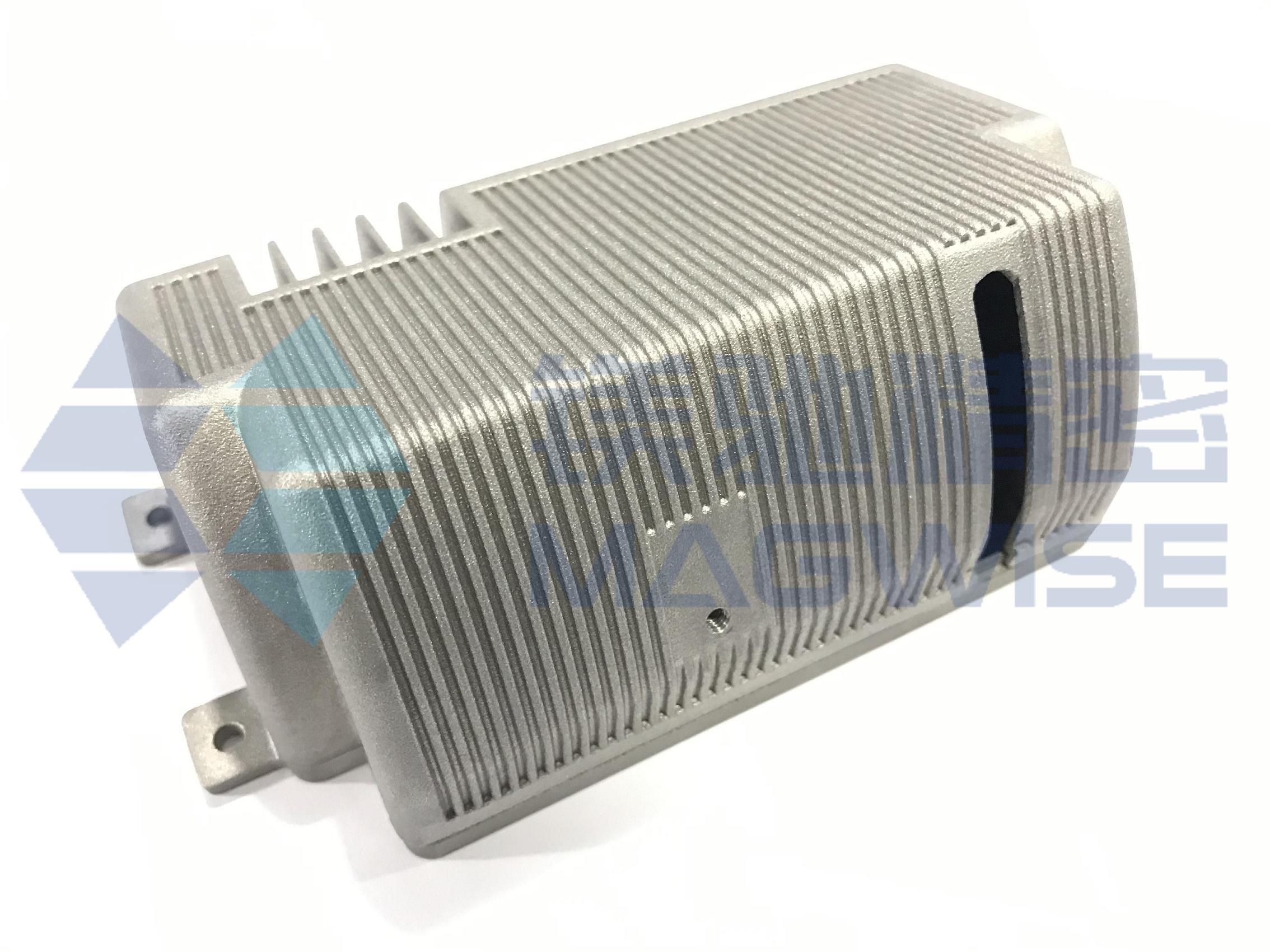

Scooter controller case

Volkswagen Germany

Inverter

Volkswagen Germany

Material Introduction (Partial)

Aluminum alloy is an alloy material made from aluminum and one or more other elements such as copper, magnesium, silicon, zinc, etc.

Aluminum alloy is widely used in many fields, including but not limited to aerospace, automotive production, rail transport, electronic equipment, construction, etc. The continuous development of technology indicates that the potential applications of aluminum alloy in the future will be even greater.

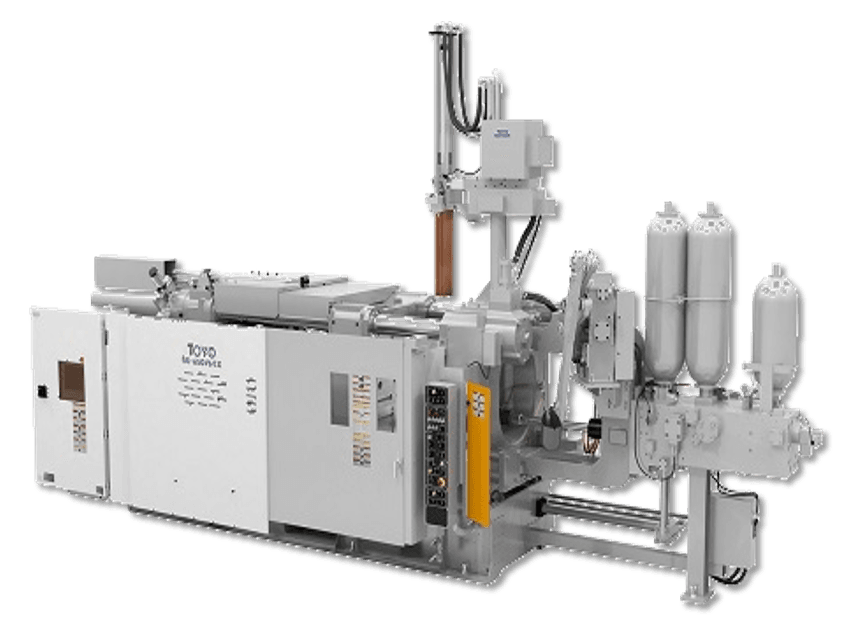

Die Casting Process

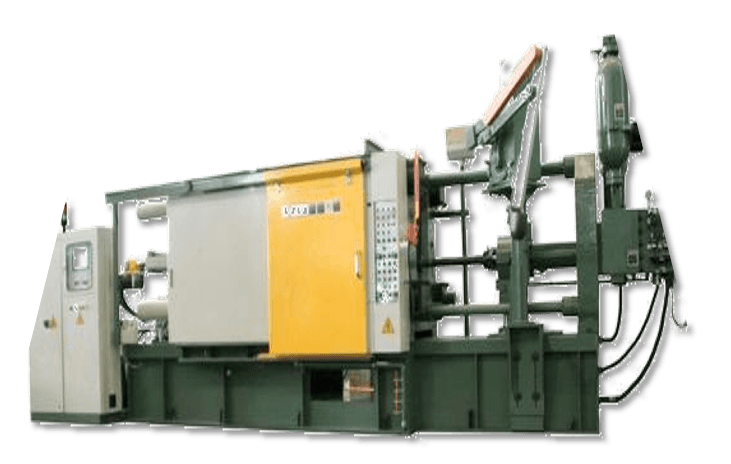

We continuously introduce the latest technology and equipment, providing strong momentum for product research and development, and production, driving the company's continuous innovation and development.

Processing equipment

Processing equipment

Processing equipment

Production equipment

Production equipment

Production equipment

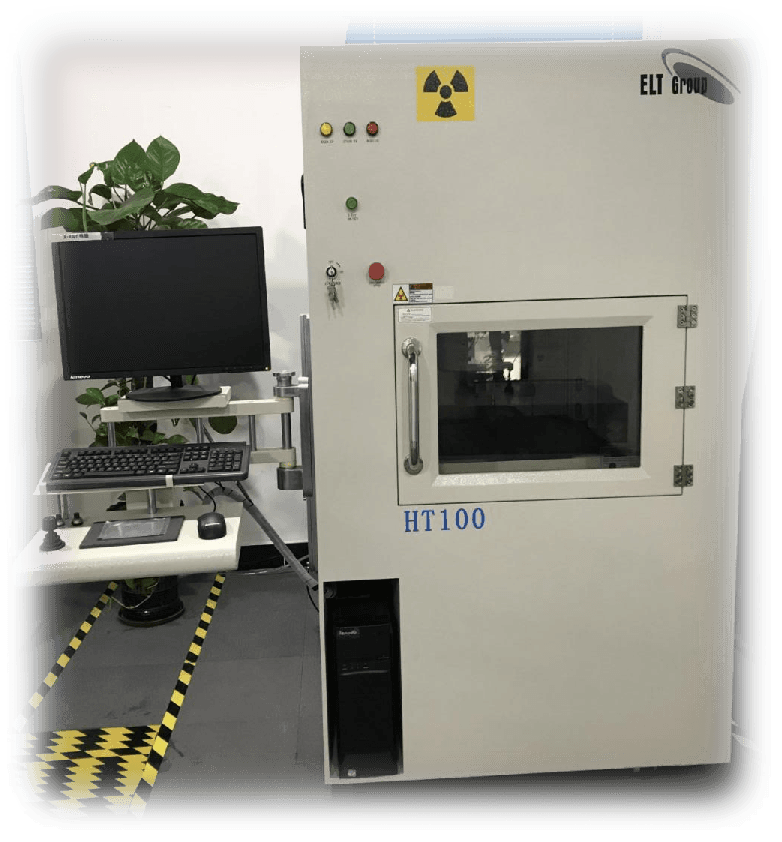

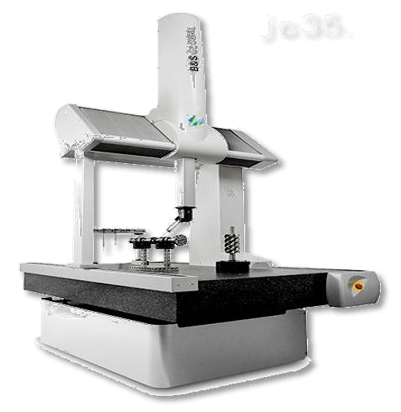

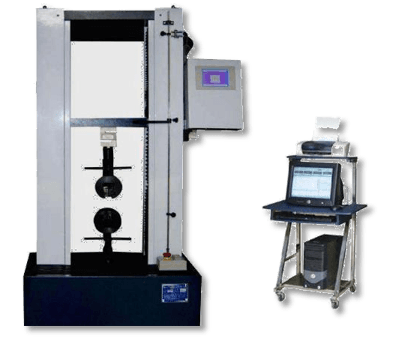

Testing equipment

Testing equipment

Testing equipment

Our products and services enjoy a high reputation in the industry. With high standards and attention to detail, we have won the unanimous praise of our customers. Over the years, we have continuously optimized and innovated, committed to providing customers with value and experiences beyond expectations. It is this pursuit of excellence that has earned us the trust and long-term support of many customers.